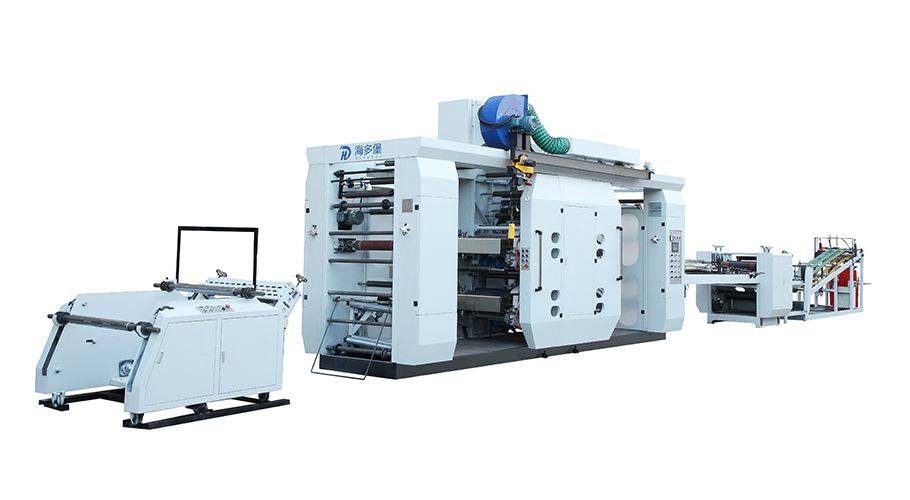

The laminating type printing machine means that each color group is separately equipped with small-diameter rollers.

Purpose:

It is used for printing of PP woven cloth and paper-plastic composite coiled materials. After printing, it can realize winding or be connected with the bag making unit to form an integral machine. It is used for making cement bags, flour bags, rice bags, feedstuff bags, compound fertilizer bags, aquatic product packaging bags, frozen meat packaging bags, putty powder bags, chemical bags, plastic granule bags, etc.

Being devoted to meeting bag making demands in the industry, wholeheartedly serving PP woven packaging customers, professional PP woven cloth production equipment.

Equipment performance and features:

●Flexible cloth running, adjustable color numbers at the front and back, mature and stable structure and high market share.

●The advanced cloth control system including tension control and deviation correcting devices ensures stable color registration.

●Cast iron wallboard. The upper and lower beams are welded by channel steel, and the advanced construction process meets the need for long-term stable operation of the machine at high speed.

●The frequency conversion motor automatically adjusts according to speed changes. The color group is driven by the synchronous belt. High precision and low waste at machine starting and stopping.

●Automatic ink supply, pneumatic roller lifting at the time of stopping, durable stainless steel ink cartridge.

●The closed high-speed circulating oven is energy-saving and environment-friendly.

●Deflectable and displaceable forming, stable gas emission without scratching or damaging the bag.

●Double servo power small hob, low vibration, noise and energy consumption, automatic collection of waste pieces, conducive to cleanliness management of the workshop environment and clean returns.

●Consistent direction of false cut valve mouths, stopping of bag stacking at the fixed number level, low labor and labor intensity, and easy work of employees helps to reduce the management cost.

●Accessories of internationally first-class brands, nationally first-class manufacturing processes and nationally first-class brand service.

●Low noise and internationally standard safety protection design, beautiful and decent equipment, low investment, little maintenance and medium benefit.

* Summary: Compared with planetary products, due to its simple, mature and stable structure, it can be additionally provided with optional fittings to ensure precision and increase its service life on the market.

Technical parameters:

|

Maximum printing width |

600mm |

|

Printing length |

700~1000mm |

|

Registering precision |

±2mm |

|

Printing color number |

5~8 Colors |

|

Winding and unwinding diameter |

≤1400mm |

|

Printing speed |

60-140m/min |

|

Main motor power |

5.5kw |

|

Outline dimensions |

23000×2300×3500mm |

Configuration list:

|

Servo motor |

Delta |

|

PLC |

Delta |

|

Bearing |

Zhejiang Renben |

|

Wallboard material |

Cast iron |

|

Touch screen |

Weinview |

|

Switching power supply |

Mean Well |

|

Low voltage electric appliance |

Schneider |

Appearance of the application scene

Operating state appreciation

Print This Page

Print This Page Bookmark This Page

Bookmark This Page Send Email

Send Email

Message

workday:7:30-17:00

Online Message